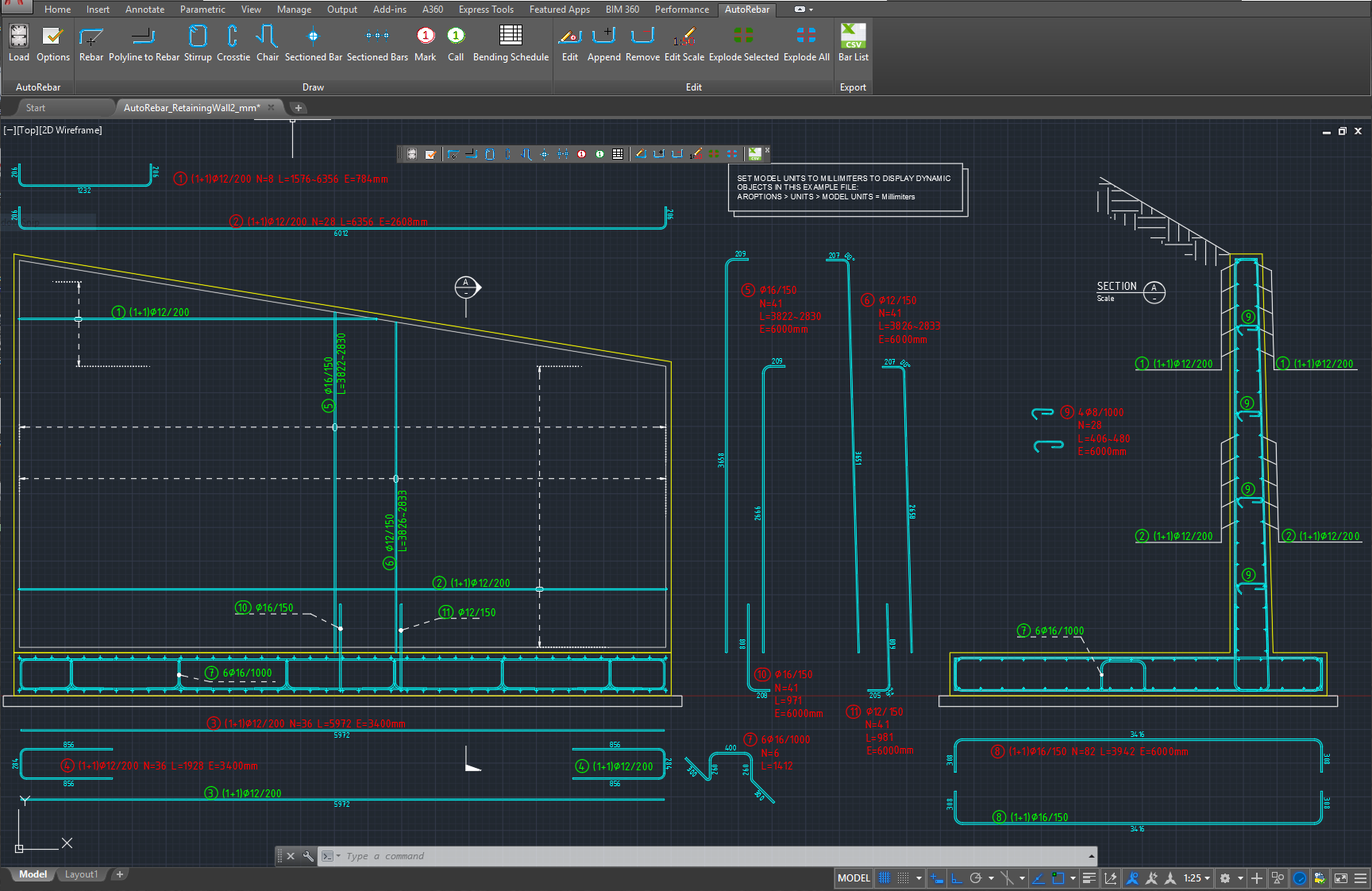

TEKLA: CONSTRUCTING WITH CONFIDENCE

"Tekla is the cornerstone of our construction process, enabling us to build with unmatched confidence. Its advanced capabilities streamline our workflows, allowing for seamless collaboration and the creation of structurally sound steel designs."

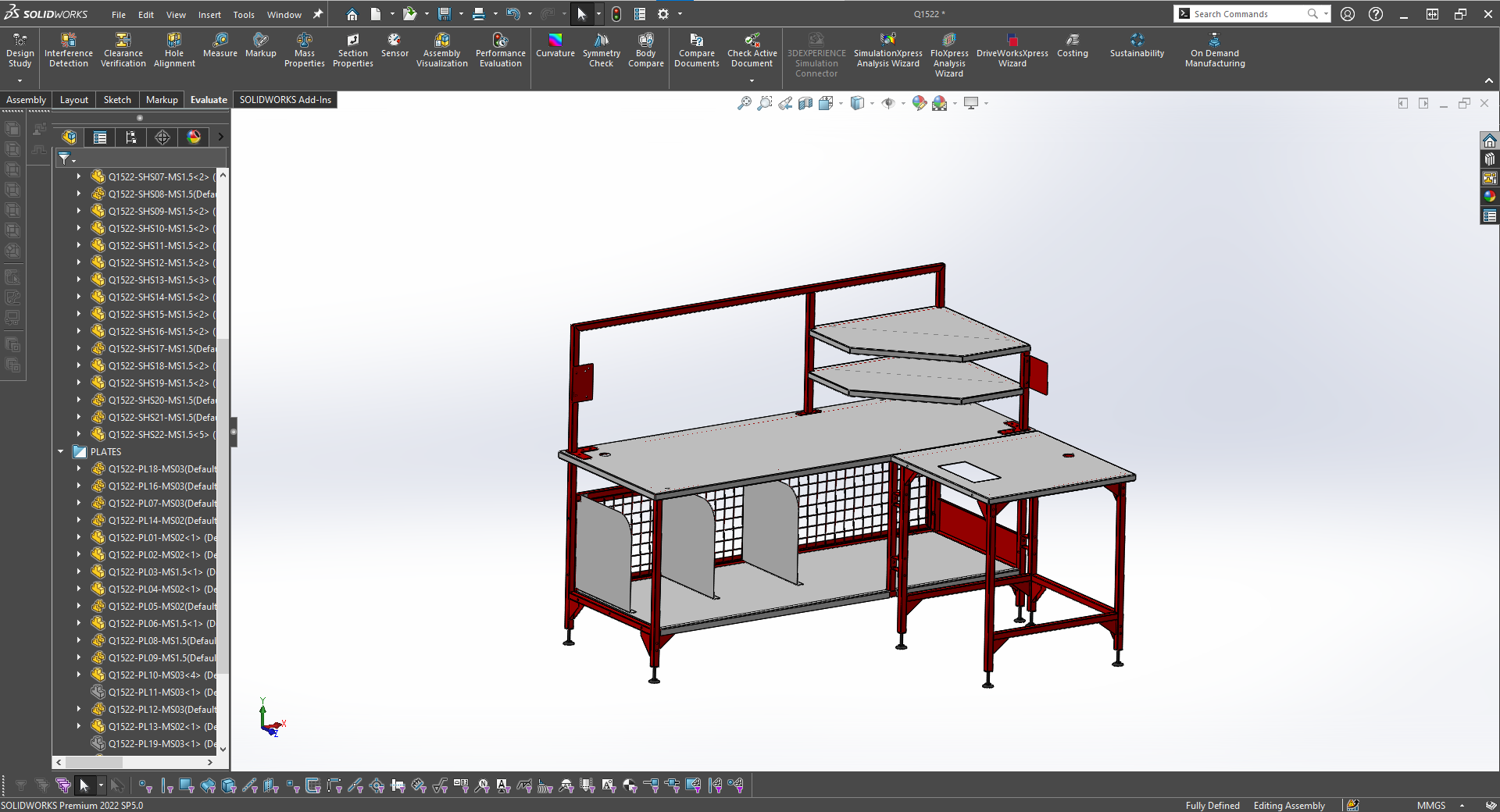

SOLIDWORKS: PRECISION IN DESIGN

"SolidWorks is our trusted design companion, ensuring precision and accuracy in every steel structure project. With its powerful features and intuitive interface, we craft designs that meet the highest standards."

AUTOCAD: TURNING IDEAS INTO 3D DESIGNS

"With AutoCAD, we analyze client requirements, produce drawings, and we ensure accuracy and efficiency throughout the design and construction phases."

AMADA LASER - CUTTING MACHINE

"The AMADA LCG3015AJ II is a highly efficient fiber laser cutting system suitable for a wide range of materials. It offers better productivity by allowing you to work with various materials without lens changes. This advanced system features automatic nozzle changing, expanded processing capabilities, and high- pressure air cutting. It's easy to operate with the AMNC-3i interface. With a 3000W laser power, it can handle mild steel (up to 19mm), stainless steel (up to 15mm), aluminum (up to 12mm), brass (up to 8mm), and copper (up to 6mm)."

AMADA PUNCH MACHINE

the AENT series is a line of single AC servo drive turret punch press with Amada’s original "Highly Rigid Bridge Frame” "Our AE Series turret punch press offers precision and efficiency for your sheet metal processing needs. With a press capacity of 200 kN (20 tons) and tool storage options of 45/51/58 stations, it's versatile and adaptable. You can work with sheets of sizes up to 3000 x 1500 mm, with thicknesses up to 6 mm. It maintains punching accuracy within ±0.1mm and ±0.07mm (FA mode) and achieves high hit rates, with a rapid feed rate of up to 80 m/min. Our turret punch press simplifies complex tasks like deburring, slotting, marking, and forming, making your sheet metal work efficient and precise."

AMADA PRESS BRAKE

Our HRB Press Brake Series simplifies precision bending with industry-leading technology. It's versatile and user-friendly. These press brakes offer press capacities from 500 kN (50 tons) to 1000 kN (100 tons). Table lengths vary by model, with the longest at 3000 mm. Notable features include natural crowning, higher longitudinal accuracy.

AMADA GUILLOTINE MACHINE

The Amada Guillotine Machine, is an industrial cutting tool designed for precision shearing of sheet metal. It employs hydraulic or mechanical mechanisms for accurate and clean cuts across various sheet metal materials and thicknesses, known for its versatility, safety features, and durability. The capacity of Guillotine includes a maximum cutting length of 3 m and a cutting thickness capability of up to 3 mm.

MAZAK TUBE LASER-CUTTING MACHINE

The 3D FABRI GEAR 400 III is a versatile and high-performance laser- cutting machine designed to handle a wide range of materials and shapes , including tubes, pipes, I and H beams, and various structural elements made from mild or stainless steel. With a powerful 6-axis laser, it offers precision cutting at different angles, ensuring accurate assembly fit-up. Its automated functions make it efficient for both small and large-volume part production, making it an ideal choice for diverse industries and applications.THE SECTIONS CAN LOAD UP TO 8000mm,AND 100 KG PER METER

TUBE BENDING

AMOB has developed a specialized Tube Bending Machine designed to meet the precise needs of tube, coil, and panel manufacturing. With advanced CNC technology, we excel in achieving tight-radius bends with minimal deformation, especially when wall thinning is critical. Our innovative booster device, combined with a hydraulic CNC machine, ensures precision, reduces process times, and eliminates errors. With a capacity of up to 420mm, we lead the industry in efficiency, offering state-of-the-art machinery and tooling for the boiler production sector, including features like compound tooling and serpentine tooling. Plus, our CNC models allow for online troubleshooting, enhancing overall reliability.